Wash plant specification tables are set at this step. Wash plants are disabled by default; if enabled, a wash plant node displays in the material flow diagram palette. Once a site uses a wash plant node it cannot be removed.

To use the wash plant functionality, the coal wash data is required. The data must be imported into principal fields. The Field Lookup panel allows the PO to find the wash data for optimising and blending.

Due to the large number of fields involved in wash plant configuration, there is a template feature to assist in the creation of wash plant principal fields.

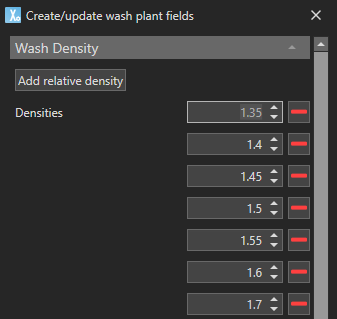

Click the Create fields ... button to open the dialog to create the wash table principal fields. The principle fields are named after the entered density and quality codes.

Wash Density (cut points): Click Add relative density and add a new principal field relative density template value. The value will be transformed to entered value x 100, for example 1.45 becomes 145.

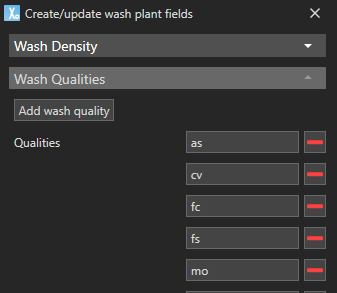

Wash Qualities: Each wash quality field will be appended to each relative density string. Click Add wash quality to add a new wash quality name part to the principal field. For example, for relative density values 1.35 and 1.45, adding CV creates principal fields 135CV and 145CV.

Required Mapping: lists fields that are used in the weighted average calculations and cut-point lookups. See the table below for Required Mapping field definitions.

Once the principal fields have been created they can be reviewed by going to System Configuration > Principal Fields.

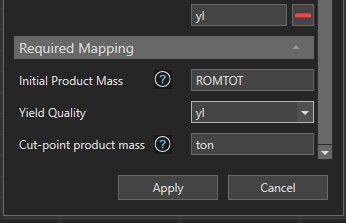

The image below shows an example of a wash table after the wash plant principal fields have been created.

The table below describes the fields in the Create Fields dialog, and the Wash Plant screen.

| Field | Description |

|---|---|

| Is Wash Field Expression (Field Lookup) | The expression that identifies any wash plant principal fields. The default expression looks for fields that start with 1. For example, principal fields 135Ash, 145CV, 155Yld will all be included in the wash table. |

| Relative Density Expression (Field Lookup) | The expression that identifies the wash table relative densities (cut-points). Using the example fields above, the default expression converts 145CV principal field to 1.45 so it is mapped to 1.45 Relative Density in the wash table. |

| Wash Quality Expression (Field Lookup) | The expression that identifies the wash table quality fields. Using the example fields above, the default expression converts 145CV principal field to CV, to enable that field to be associated with the CV wash table quality. |

| Yield Quality (Required Mapping) |

This is a mandatory mapping field so PO knows what yield suffix to look for when cycling through the various cut-points. The yield field for each cut-point is the percentage of coal (Product Tonnes) that would report to product if the coal was to be washed at that cut-point. The drop-down list includes each of the qualities detected by running the wash quality expression over the "wash data fields". It is equivalent to setting the Yield Quality in the Wash Fields tab of Scheduler step 6.4. Errors will be generated if an incorrect field is selected. Errors are displayed at the bottom of the panel. |

|

Initial Product Mass (Create fields... > Required Mapping) |

The principal field that is used as the weighting field the wash table yield fields. This is a mandatory mapping field to configure the PO with the raw mass of product included in the block. This could be set to the default Mass principal field, but it allows an alternative field to be defined which excludes the effect of any dilution. This is the field that will be used, in conjunction with the yield quality, to determine the mass of 'product' material produced by the wash plant. It must be a numeric Sum type field. It is equivalent to setting the Initial Value of ProductTonnes in the Optimised Fields tab of Scheduler step 6.4. |

|

Cut-point product mass

|

The name of the field extension that will be used by XECUTE when it generated fields for each cut-point. The created field will hold the value of the mass at each cut-point. This mass is used to weight average each of the wash qualities (other than the yield). |

| Wash Product Initial Values |

The initial values for the optimised product fields. Product Mass must be mapped to a principal field that is used as the weighting field for the product quality fields. The remaining product quality fields are mapped to principal fields for the qualities. The wash fields will be validated to ensure there are no name conflicts with existing principal field names. |

| Wash Qualities | A table of wash quality fields per relative density. |